4 Things to Look for When Buying a Pre-roll Machine

If you’ve decided to get started with automation for your pre-roll manufacturing business – you’re in the right place! There are many options on the market and your unique needs should be taken into account before investing.

At PreRoll-Er, we prioritize upfront education so you can make an informed decision about buying a pre-roll machine. From filling techniques and product quality to reject rates and financing options, there’s a lot to consider before taking the leap towards automated pre-roll production.

Here are the 4 things you need to look for when buying a pre-roll machine to automate your cannabis business:

1. Pre-Roll Filling Technique

Filling Instrument

Filling units is arguably the most important step in the process of pre-roll manufacturing.. There are different ways to fill and weigh the products, but there are serious implications for each method. When you’re looking for an automatic pre-roll machine, it’s critical to ask your supplier what filling instrument their pre-roll machines use.

In most cannabis production applications, a feed screw – also known as an auger – is used. The feed screw turns within a cylinder (aka a barrel) in the injection process to provide a uniform material flow. You may see this work for packaging spices or coffee grounds.

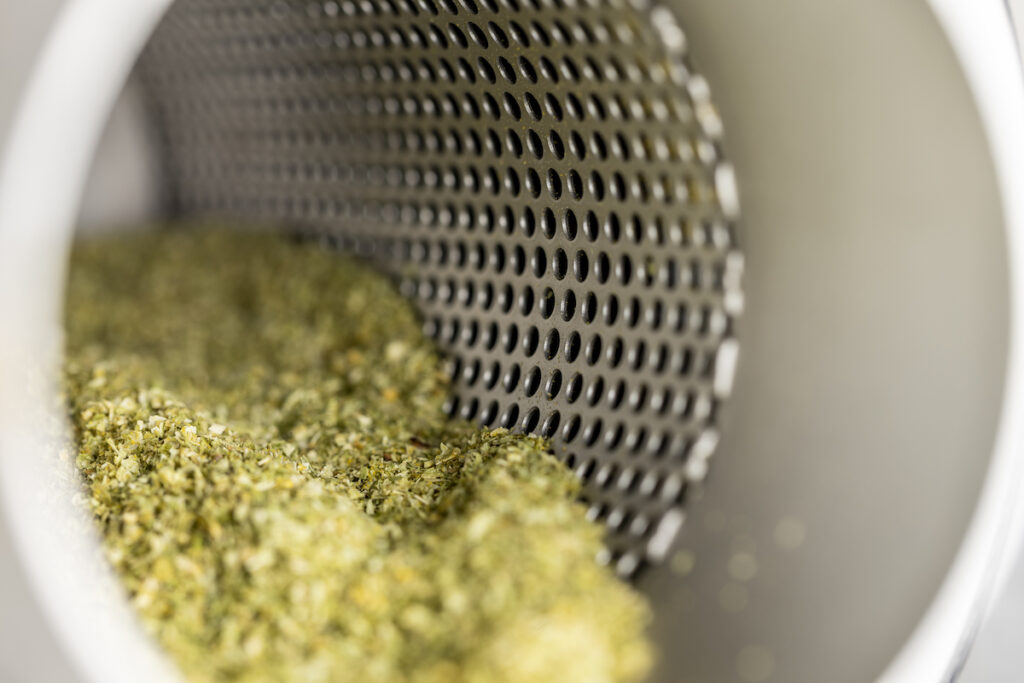

Many pre-roll manufacturers will use this same method, except here’s the difference: when you’re working with material like coffee or spices, you are working with fine, dry powder-like substances. However, when working with cannabis flower, it is a sticky, resinous substance.

Given all the components of the cannabis plant, using a feed screw results in a messy aftermath. Not to mention, you’ll have to clean it thoroughly after each strain production, meaning you’re signing yourself up for extended downtime between pre-roll production runs.

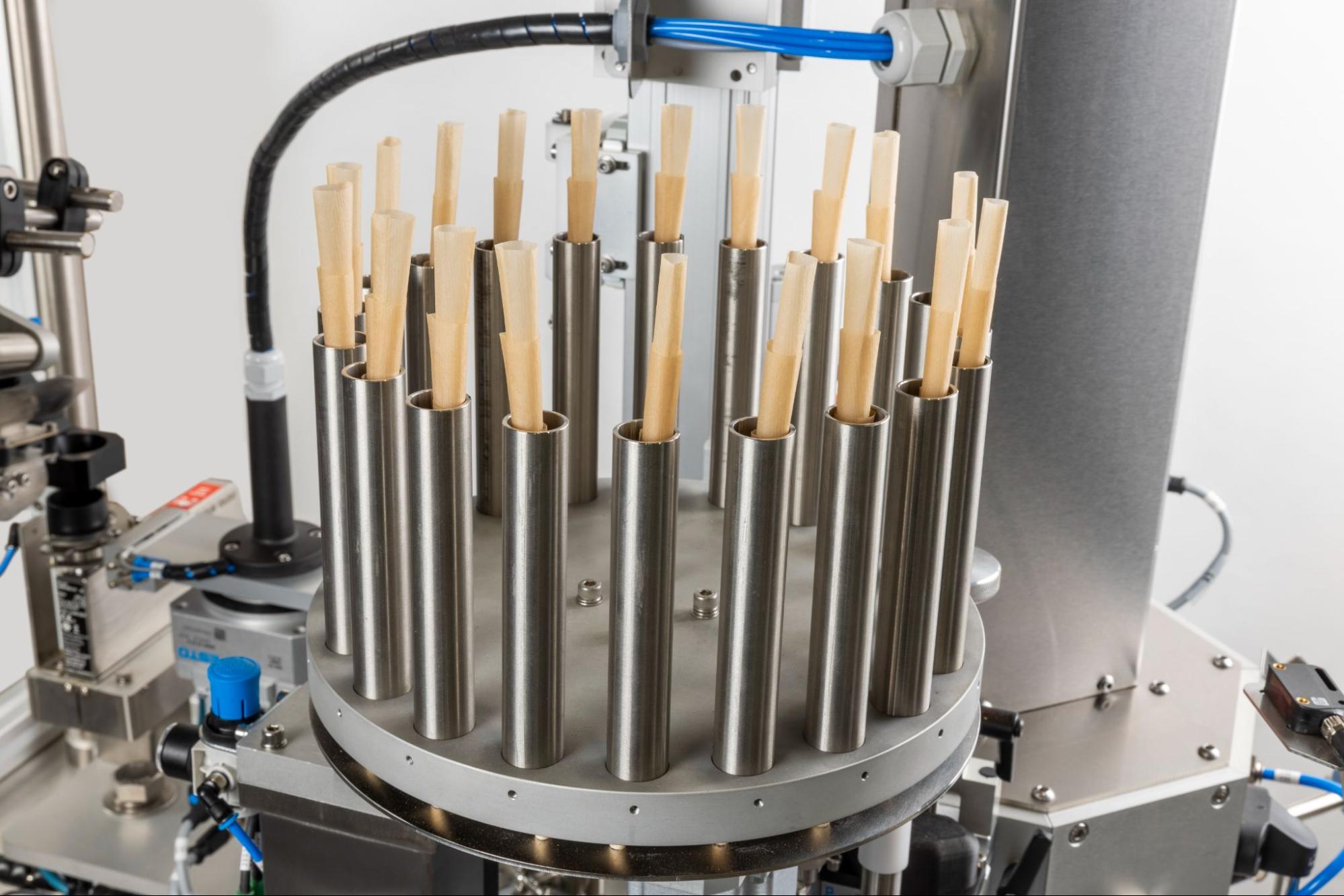

Our team at PreRoll-Er uses a scale and rotating tumbler for our automatic pre-roll machine. With these instruments, you have more precise fills and can clean between runs more efficiently. You can even have more than one (tumbler or scale) to swap out if you need – making it a versatile option compared to the feed screw.

Filling Preparation

Another process that many cannabis manufacturers use before filling their pre-roll cones in manufacturing is vibration.

This can result in a serious risk to your business because it will severely compromise the quality and potency of your end product. It also results in nearly 10% of total raw material waste that becomes completely unusable during your pre-roll production.

During the vibration process, trichomes are broken and shift all the way to the bottom. This causes a loss of overall THC potency and also skews your testing results when it comes to measuring and weighing the amount of product in each unit.

Think of when you put honey in your tea– it sinks to the bottom. Without stirring, you’ll be left with a spoonful of honey at the end of your drink, rather than an even level of sweetness throughout the tea.

Similarly, if all the trichomes are sitting at the bottom, injecting pre-rolls after vibration from an automatic pre-roll machine will cause your first batch of pre-rolls to be low in potency and density, while the end of the batch will be high in potency and density.

Long story short: if you use vibration to pack your cannabis into your pre-rolls, you won’t achieve product consistency and your customers will notice.

2. Final Product Quality

When you’re shopping around for automatic pre-roll machines, ask yourself: Will this machine produce a complete final result?

As we’ve discussed in our PreRoll-Er Reality Check series, not all pre-roll automation machines are the same. Other manufacturing machines may not close, twist, or cut the final product as PreRoll-Er machines do. In other words, the number of pre-rolls you’re producing per hour still requires manual labor to finish each unit and prepare them for final packaging.

If you ask us, that’s not real automation.

With our equipment, you get an automatic finish of your choice (Dutch crown top, flat top, etc.), meaning the 1,000 pre-rolls you produce are complete final products.

3. Reject Rate

When buying an automatic pre-roll machine, be sure to inspect the reject rate carefully. Our pre-roll machines have specified reject stations that automatically discard subpar pre-rolls, so you don’t have to inspect every single one of your final products by hand.

These machines produce a 1.9% rejection rate – the best in the industry. In other words, less than 2% of all your products will be unusable to the final customer. When you have a production of 1,300+ pre-rolls per hour, that’s unmatched.

Check out our article “What is your production rate, really?” to learn more about how other companies may be misrepresenting their reject rates.

4. Financing Options

Finally, one of the most important factors for stakeholders to consider when buying a pre-roll machine is finance. Automatic equipment is a large investment, but one that is well worth it in the long run. In fact, financing doesn’t have to hold you back from automation.

From easy scalability to stability during times of workforce uncertainty, automation provides you with a strong advantage to continue to grow your business. Maybe you have to pitch the idea of getting this type of equipment to the decision-makers in your company, or maybe you have to take some time to really consider the costs.

Regardless, financing options are important to take into account when looking for an automatic pre-roll machine. Most suppliers will give you a lease or buy opportunity. However, at PreRoll-Er, we have three options to choose from:

- Short-term financing for 6 months at 9% interest

- 36-month leasing with 0% interest, including maintenance, optimization, and cones (optional)

- Buyout with upfront payment

With this type of flexibility, you can get started with automation for your cannabis business sooner rather than later.

It can be tempting to opt for a significantly cheaper machine, particularly those sourced from Eastern countries. However, we caution you to do your due diligence and understand the effect it can have on your product integrity.

Cheap cannabis manufacturing equipment is often produced with subpar parts and engineering, ultimately resulting in poor-quality pre-rolls that you will have your brand’s name on. Not to mention, the after-sale service is non-existent, and due to the bad reputation, you will not likely be able to get the support of any other supplier or manufacturer should you have any challenges.

While automated pre-roll and cannabis processing equipment can be overwhelming to finance, the truth is that you get what you pay for. Therefore, investing in industry-leading pre-roll machines that come with tailored support services is key to being able to move efficiently when investing in automation.

Ready to automate your cannabis business?

If you’ve read to the end, then you are serious about automating your cannabis operation and scaling it to new heights – and we’re here to help. At PreRoll-Er, we’ve helped hundreds of cannabis companies grow their operations through automation.

We can give you estimates and break down the solutions that are best suited for your unique business. To get started, speak with one of our team members today.