Automating Your Operation for Infused Pre-Roll Production

It’s no secret that pre-rolls have increased in popularity, despite years of relatively flat growth in the market.

In Canada, the product category is the second largest, and a recent report, revealed that infused pre-rolls have grown tremendously from 6.2% of total sales in January 2022 to 29.8% by February 2023, a growth rate of nearly 606%

The numbers say it all: infused pre-rolls can grow your business.

At PreRoll-Er, we see this trend grow as customers ask about the injection and infusion capabilities of our pre-roll automation equipment. Our answer? We can do it all.

Here is everything you need to know about how to automate your operation for infused pre-roll production.

Injection vs. Infusion: What’s the difference?

Injected and infused pre-rolls are both typically marketed as “infused” for the end consumer. However, both are manufactured in different ways and can influence a business’s decision as to how to infuse their products, what equipment to prioritize in their equipment stack, and more.

Depending on the size of your operation, you may choose one type of pre-roll automation equipment over the other to select injection/infusion. At PreRoll-Er, we meet you where you are and give you the most versatility with our products: the PreRoll-Er 200 and our BoxFinish-Er.

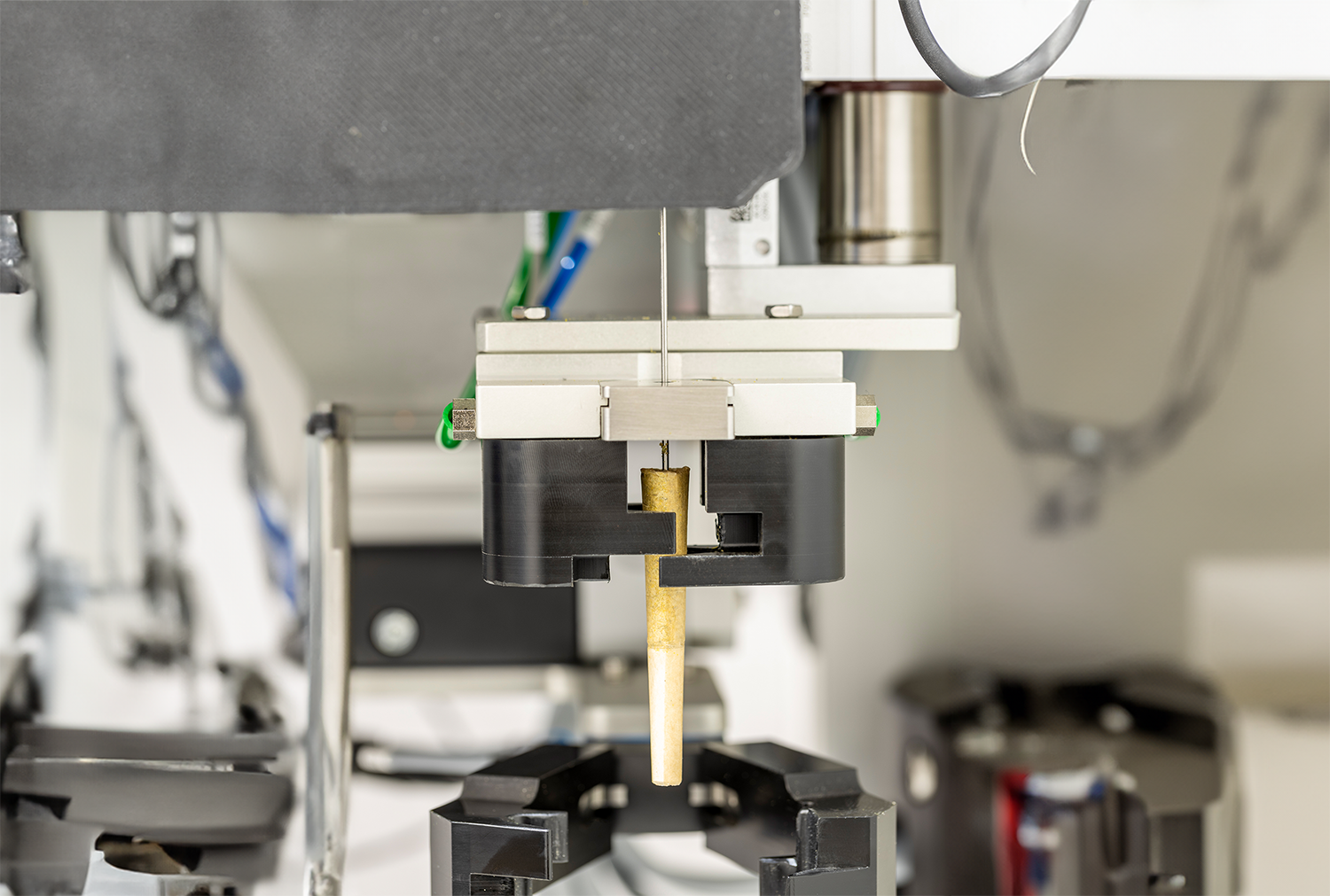

Injected pre-rolls involve a needle-like device that incorporates concentrated cannabis oil or distillate directly into each unit, one by one. On the other hand, infused pre-rolls add oil to the flower in a bin, shake it up, and then move on to the filling process.

These processes allow for a uniform distribution of cannabinoids throughout the pre-roll, providing a potent and consistent smoking experience.

How to automate injected pre-roll

Many injected pre-roll machines on the market are not fully automated; they are semi-automatic. This means that you need to manually load cones into the machine.

PreRoll-Er has the only machine on the market with an injection system integrated into the machine, making it so that you don’t need to transfer the finished pre-rolls to another machine.

Motorized injection allows for a controlled distribution of concentrated cannabis oil or distillate into the flower materials. It also streamlines the process, making it faster and more scalable, ultimately allowing you to produce higher volumes without compromising on quality.

A fully automatic pre-roll machine is therefore necessary to get the best value and the best end product.

Terpenes are volatile compounds. They have precise temperature zones to “activate” the terpene – overheat them and you can change their chemical composition or lose the aromatics and flavor properties.

Semi-automatic machines may not allow you to set a precise temperature zone, meaning you risk overheating terpenes and ruining the quality of your pre-rolls.

Our machines – the only fully automatic solutions on the market – provide three custom heating zone settings so you can not only manufacture a pre-roll of a certain terpene makeup accurately but also ensure that nothing is going to clump up in the infuser (distillates solidify very quickly).

How to automate infused pre-rolls

When automating infusion, it’s important to look for a machine that has high-quality parts to make this the most efficient process possible. In general, infusion can be a messy, sticky process.

When you’re adding a sticky oil or concentrate to infuse your raw cannabis material, it can create several difficulties:

- Machine jamming

- Difficulty in transferring or cleaning the infused material from the machine

- Loss of product at the end of the infusion process

- Sticky end product and poor smoking experience

That’s why we offer an AC unit and sub-zero tumbler add-on to our PreRoll-Er 200. With these add-ons, you can lower the temperature on the machine and in the tumbler itself, so the product becomes less sticky and flows through the machine better. Not only does this extend the lifespan of your equipment but also speeds up the manufacturing process and results in a higher quality end product.

Automate your infused pre-rolls with PreRoll-Er

As pre-rolls grow in popularity, consumers are looking for a variety of options in the category: flavor, strains, experience, and more. Regardless of whether you choose to inject or infuse your pre-rolls in your manufacturing process, it’s essential to set yourself up for long-term, sustainable success.

Meet demand by scaling your production capacity to include fully automated pre-roll production. Talk to a member of our team for a one-on-one consultation on how to incorporate automation into your process. Get started today!