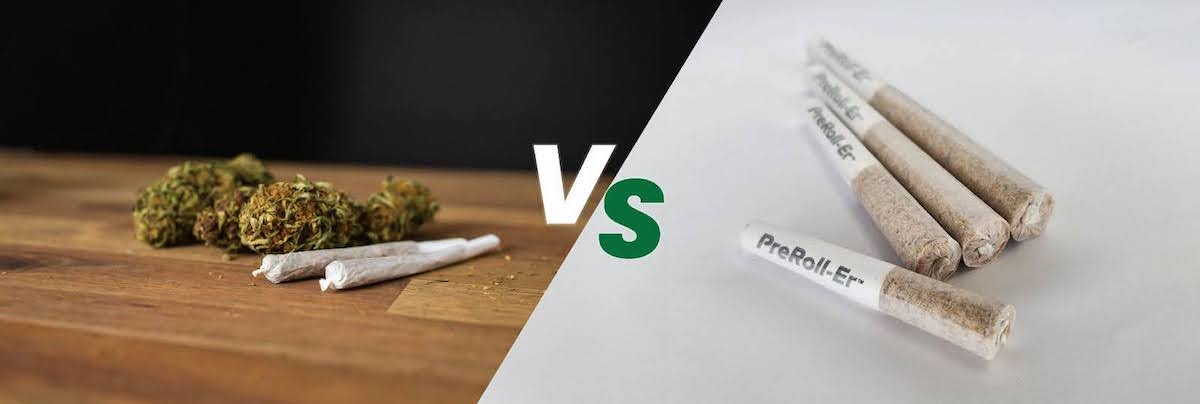

PreRoll-Er Reality Check: Is hand-rolled always better?

When it comes to pre-rolls, there’s a mystical element around the rolling process. Consumers enjoy them because they’re not the ones who have to put in the work, but somehow, it feels better to know you have a hand-rolled joint…or does it?

Dispensary owners are noticing that consumers have responded with surging interest in infused pre-rolls and operators are increasingly investing in this category. According to experts, infused products have grown so fast in comparison to other segments within that [pre-roll] category. We’re looking at easily a five-times increase since January 2020.”

With such a rapid increase in consumer interest, it goes without saying that the market is going to respond accordingly. However, are hand-rolled infused pre-rolls really so much better than automated pre-rolls?

We’ll find out. In the second installment of our Reality Check series, our team is uncovering the realities of hand-rolled versus automated pre-roll production.

Reality Check 1: Automation actually saves time.

As a manufacturer, it’s important to optimize your production process. From accurate output forecasts to easy scalability, automation proves to be superior to hand-rolled pre-roll production.

For instance, if the pre-roll market continues to grow at this rapid rate, manual processes will have to figure out how to keep up with demand without the burden of increased labor costs.

Not to mention, having employees hand-roll hundreds of joints is no easy task and can even lead to repetitive strain injuries such as carpal tunnel and other similar syndromes. Not only does this directly affect things like company well-being, morale, and even labor costs, but it can lead to decreased productivity and attendance.

Key takeaway: Hand-rolled pre-rolls do not allow for consistent measurement of productivity and can, over time, result in unforeseen time and cost expenses.

Reality Check 2: Automation actually improves consistency.

Consumers who like pre-rolls because of the convenience are going to value a consistent, reliable experience. While manual packing methods can offer a unique appeal, human performance variability can result in differing production rates.

Hand-rolled joints can vary in quality and consistency depending on the skill of the person rolling them. Automated pre-rolls, on the other hand, are typically consistent in terms of the amount of cannabis they contain, making it easier to control your dosage.

This is because automation equipment like PreRoll-Er’s machinery gives you control over exactly how the joint is packed and finished, which can influence the smoking experience.

Key takeaway: Automation allows you to provide a repeatable, consistent quality – and consumers value a reliable experience!

Reality Check 3: Automation actually prevents the loss of raw material.

Both hand-rolling and automating pre-rolls can lead to the loss of cannabis flower.

Inefficient machines, such as a pre-roll cone filling machine, will excessively vibrate to fill each unit’s cone. This can lead to flower spilling all over the place – not to mention, an insufficient compaction.

Similarly, hand-rollers cannot ensure an exact science to the amount of flower that goes in each pre-roll, meaning the volume and compaction of raw material will vary from unit to unit.

Not only does this mean you’re losing potency, but you’re also losing the time and money you invested in your raw materials (sourcing, harvesting, drying racks, etc.).

Avoiding this requires asking the right questions and triple-checking your automated pre-roll machine supplier. To learn more about what you should be asking before purchasing equipment, check out our blog “What is your production rate, really?”

Key takeaway: The most efficient and sustainable productions use high-quality pre-roll machinery.

Reality Check 4: Automation actually improves the quality assurance process.

Most brands argue that hand-rolled pre-rolls offer a unique appeal. However, that appeal mainly comes from the perceived quality of the joint. In fact, there is a misconception that automation compromises the final product’s quality, but this couldn’t be further from the truth.

Automated pre-roll machines, like the ones we provide at PreRoll-Er, can be integrated with quality assurance systems. From sensors that detect anomalies in total unit weight to a reject station built into the machine, our equipment helps make quality assurance a breeze.

Key takeaway: Hand-rolled pre-rolls are harder to quality-check, whereas automatic pre-roll machines blend seamlessly with various systems to ensure consistent quality across production runs, regardless of strain or employee variables.

Reality Check 5: Automation actually saves money.

While the initial investment into an automated pre-roll machine is significant, automation offers long-term benefits. From cost-efficiency and easy scalability to consistent output, decreased downtime, and impressive ROI, automation ends up saving you money in the long term.

On the other hand, hand-rolled pre-rolls can run up quite a high bill. Between worker’s insurance and other labor costs and increased learning curve, training, and upskill time, hand-rolling your products can become prohibitively high.

Key takeaway: If you intend on staying in the pre-roll space for the long run, automation will save you money.

Reality Check 6: Automation actually improves the final smoking experience.

As the pre-roll market grows and new consumers explore different offerings in the industry, we’re seeing pre-rolls get a negative reputation because of their quality.

In order to succeed as a manufacturer or cannabis brand, it’s crucial to invest in your production process. When a joint is properly compacted, the temperature, burning point, and overall sensory experience are heightened.

For instance, with even, layered compaction that PreRoll-Er specializes in, you’ll get that white ash (like barbecue) that signals an optimal burn. On the other hand, black ash means you’re basically smoking tar!

This is a common experience for many consumers who reach for brands that may be hand-rolling or not using the right equipment.

Key takeaway: Using automation to produce your pre-rolls improves the smoking experience of the final product.

To automate or not to automate

As you can see, hand-rolled does not always mean better. From time and money to raw material, quality, consistency, and smoking experience, automation can help provide a reliable product to your end-users.

Don’t believe us? Cannabis sommelier Pedro Dominguez previously believed that hand-rolled pre-rolls were the best quality. However, after using PreRoll-Er’s automated pre-roll manufacturing equipment, his opinion changed completely.

Listen to what he thinks of automating pre-rolls now in our interview with Jose Dominguez.

At PreRoll-Er, we want to establish a partnership with you above all. We are dedicated to delivering tailored services to all our customers, encompassing installation, training, and maintenance. This comprehensive approach ensures that you can proactively address potential challenges, streamline your operations, meet increasing demands, and uphold product consistency seamlessly.

To learn more about us or see a live demo of our equipment, get in touch with our team today.