How to Successfully Automate Your Pre-Roll Production

Market

Pre-rolls have skyrocketed to the second-largest growth segment out of all cannabis products on the market, outpaced only by flowers. As consumers grow more interested, manufacturers are tasked with keeping up.

However, delivering the perfect infusion on a cannabis pre-roll becomes tricky – no matter how skilled your labor force is – when demand grows exponentially.

Enter, automation.

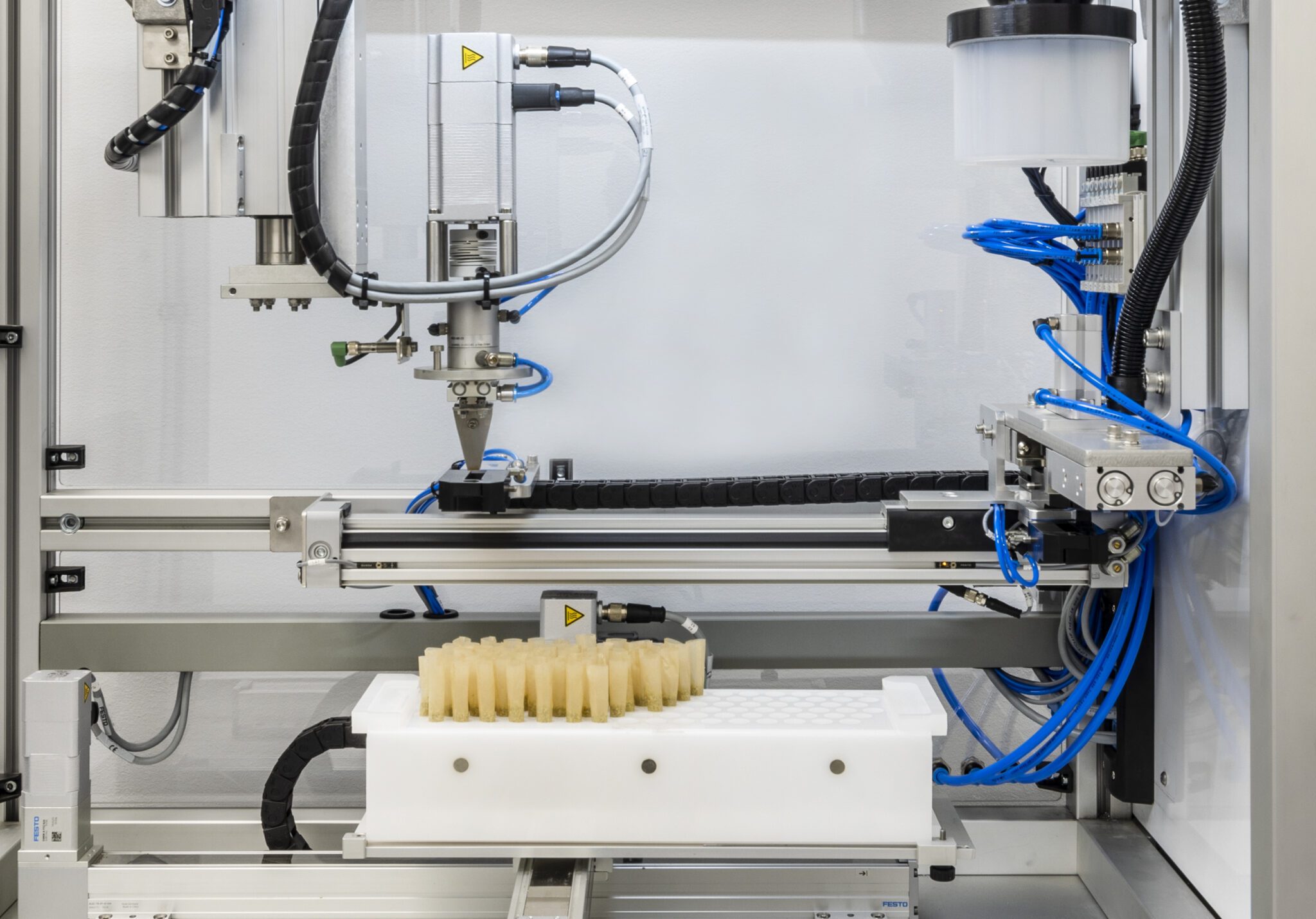

With equipment to automate your pre-roll production, you can meet market demands, reduce costs, prepare and sell a consistent product, and further scale your operations to a whole new level.

However, finding the right pre-roll machine is just part of the equation. Partnering with the right manufacturing partner is essential to ensure that you are making a good, long-term investment that can grow with you.

Here’s everything you need to know about successfully automating your pre-roll production:

Take small steps

Automation is best done step by step. Start by targeting your first needs based on budget and existing labor. For instance, maybe you want to fully automate your tube packaging. A simple automated labeler might be enough as a first phase.

You’ll want to scale in phases to ensure that you don’t run into any operations errors or mishaps. This approach will also help your existing labor force adjust to the changes being made and provide you with a strong foundation for long-term success.

Pick a partner, not a supplier

There are many pre-roll machines out there – and it’s easy to buy one. However, once you get the machine, you must maintain it for your unique needs. Select a company you trust that deeply understands automation and pre-rolls.

Francis Foucault-Bouchard, the Director of Marketing at PreRoll-Er says, “You want to make sure the equipment you select will grow with you, not become a liability later on.” As a client-first automation solution, PreRoll-Er takes time to go through its solutions, going as far as on-site training to ease the learning curve for producers that purchase their pre-roll machines.

Ensure the quality of your raw materials

The quality of the raw material you use in your pre-roll is important. When automating your production, it becomes even more so. Just as you would not put a $200 bottle of wine into a pint glass, you will not want to put good quality flowers in a bad pre-roll.

As you endeavor to increase your output through automation, be sure to look over these details, especially the humidity, grinding size, and quality of flowers. Check that your grinding size is consistent and your humidity is correct.

In summary

Automation is a guaranteed way to take your pre-roll production to the next level. The most important thing is to have a well-thought-out plan for automation. By taking small steps, selecting real experts, and ensuring the quality of your product, you can successfully scale your pre-roll operation.