Revolutionizing Prerolls: How Centrifugal Automation Delivers the Ultimate Consumer Experience

Written by Tyler Vaughan. With nearly five years of experience in the cannabis industry, Tyler brings a wealth of expertise in automation. His focus lies in preroll production and packaging machinery, where he has honed his skills and deep understanding of the challenges and opportunities of automation. As a preroll specialist, Tyler is passionate about sharing his knowledge and serving as a valuable resource for your business.

In the world of cannabis consumption, the preroll holds a special place. It’s convenient, easy to use, and provides a consistent smoking experience. However, ensuring that consistency has traditionally been a challenge, with issues like uneven density, air pockets, and voids often affecting the smoking experience. Enter centrifugal automation, a revolutionary technology that is changing the game for automated preroll production.

What Does Centrifugal Automation Mean in the Cannabis Industry?

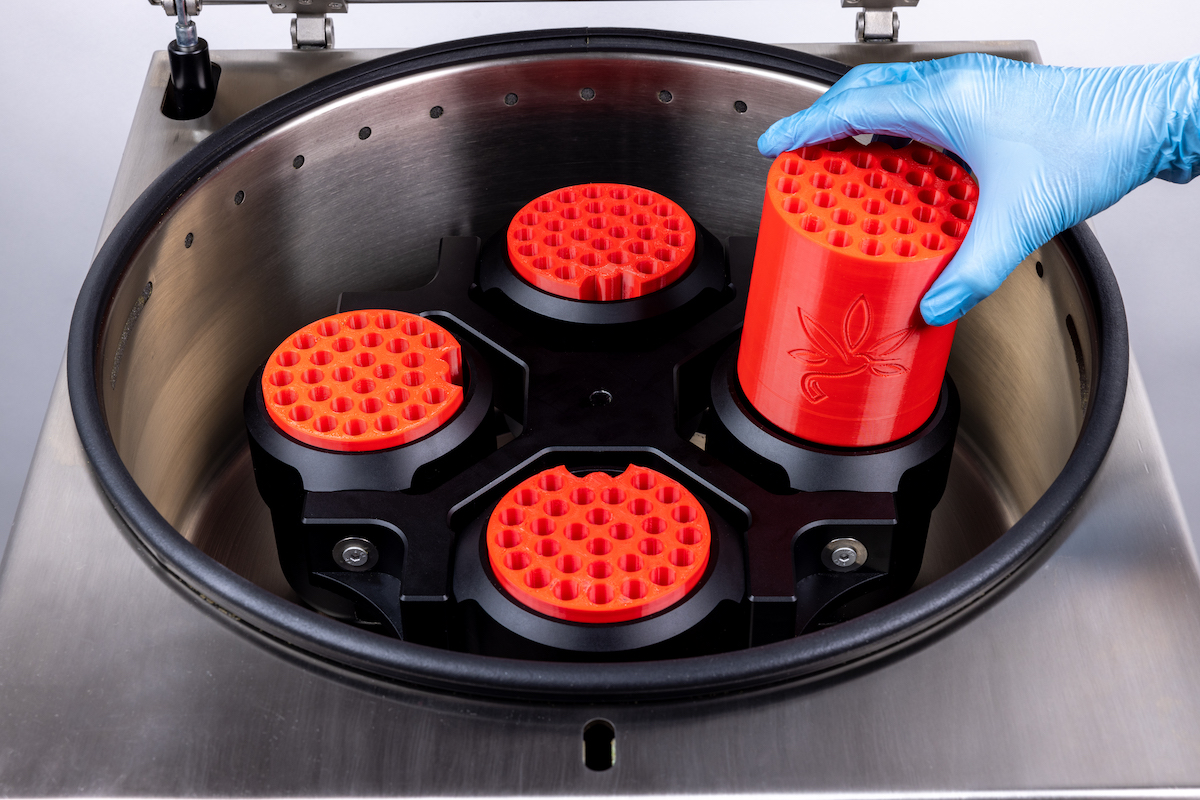

Centrifugal automation in cannabis packaging is a cutting-edge process that uses centrifugal force to compact cannabis flower into prerolls. This method ensures an even density throughout the entire preroll, from tip to end, eliminating the risk of air pockets or voids that can affect the burn and taste of the preroll.

Benefits of Centrifugal Automation in PreRoll Production

One of the key benefits of centrifugal automation is its ability to deliver a consistent smoking experience. With traditional hand-rolling methods, achieving an even density can be challenging, leading to variations in burn rate and flavor. Centrifugal automation for preroll manufacturing eliminates this variability, ensuring that each preroll delivers a consistent, high-quality smoking experience.

Additionally, centrifugal automation offers significant time and cost savings compared to traditional hand-rolling methods. By automating the compaction process in preroll production, manufacturers can significantly increase their production capacity, allowing them to meet growing consumer demand more efficiently.

Furthermore, centrifugal automation also improves the overall quality of the preroll. By ensuring an even density, the technology minimizes the risk of canoeing (uneven burning) and enhances the flavor profile of the cannabis flower.

In conclusion, centrifugal automation is revolutionizing automated preroll production for the cannabis industry delivering a consistent, high-quality smoking experience for consumers. By ensuring even density and eliminating air pockets or voids, this technology is setting a new standard for preroll production. As consumer demand for high-quality cannabis products continues to grow, centrifugal automation is poised to play a key role in meeting that demand, delivering the ultimate consumer experience.

Automated PreRoll Production Solutions at PreRoll-Er

At PreRoll-Er, we offer a wide range of pre-roll production solutions – with cannabis processing equipment such as pre-roll automation, cannabis packaging equipment, product labelers, and more. Each pre-roll equipment and solution is easy to scale and backed by quality-assured and tested technology, so you can fully maximize the potential of your cannabis operation.

View our line of cannabis equipment or learn more on our blog page. Get in touch with a representative to book a live demo.