PreRoll-Er 200

Automatic pre-rolls machine. Compatible with infused cannabis

-

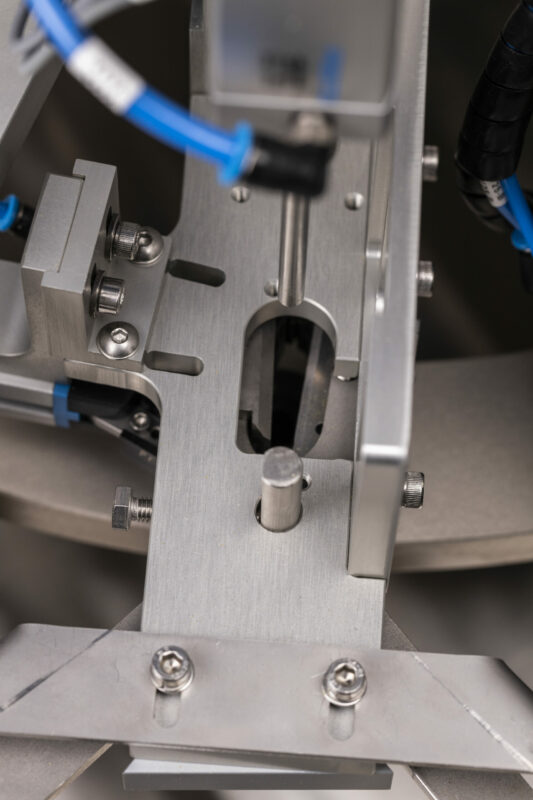

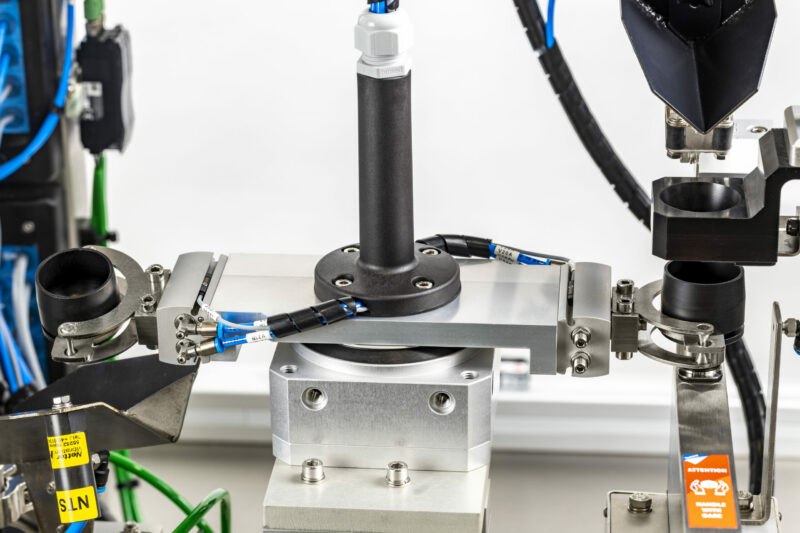

Weigh

-

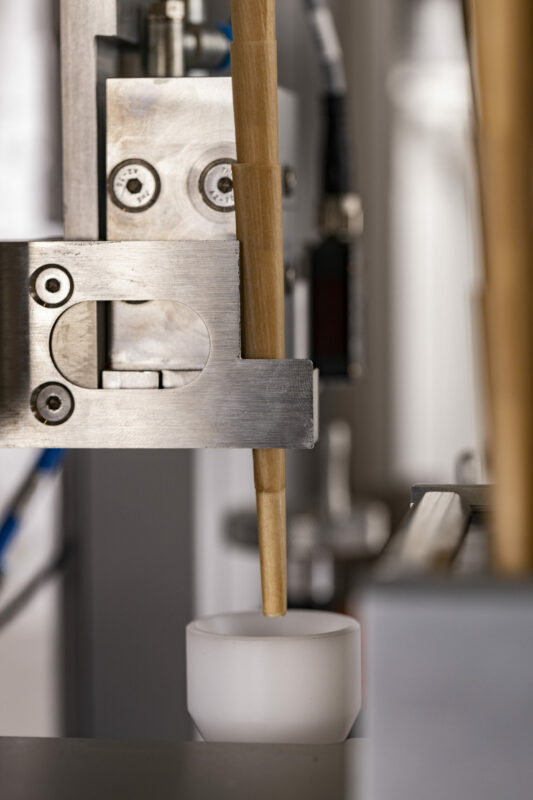

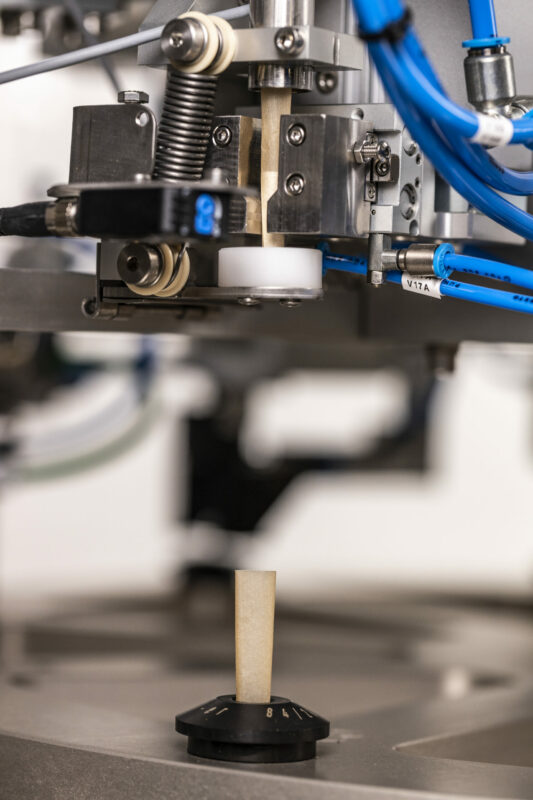

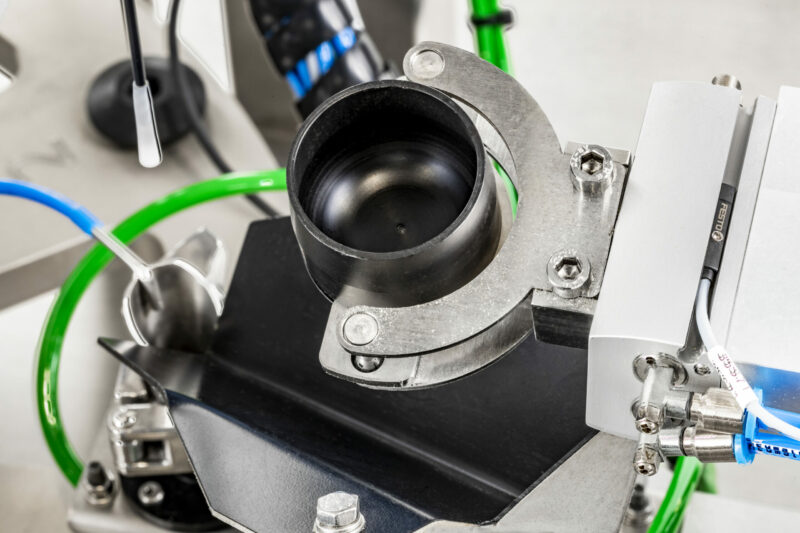

Fill

-

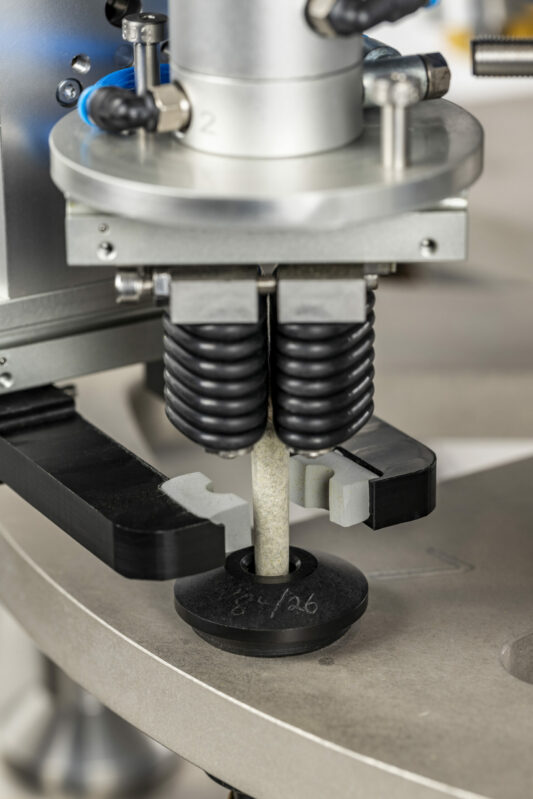

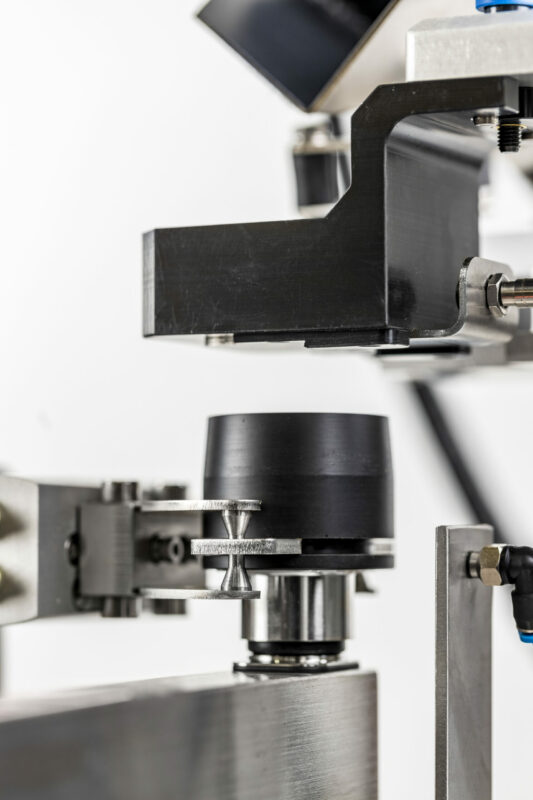

Compact

-

Twist

-

Cut

-

Inject-Er

-

Final Weigh

The PreRoll-Er 200 is our company’s flagship product. It is a pre-roll machine for cones and cylinders with automatic and semi-automatic options. Our PreRoll-Er 200 works with all type of strains, including infused cannabis, and produces up to 1,300 pre-rolls per hour. We guarantee a tolerance of 0.01 g by weighing before and after filling. Our machine can come with a direct oil injection system as an option.

Highlights

-

Produces up to 1,300 pre-rolls/hour

-

Replaces 15–20 operators per shift (rapid ROI)

-

Produces both conical and cylindrical pre-rolls

-

Works with infused cannabis

-

Guaranteed weight of 0.01 g (weighs before filling)

-

Exit weight checking with reject station

Options

-

Cones Are Auto-Loaded, No Manual Handling Required

-

Video Gallery On HMI For Maintenance And Operation Procedures

-

Visual Remote Access To The Machine With Integrated IT Camera

-

Extensive Statistical Data On Production

-

Advanced PLC + HMI Control Panel